Description

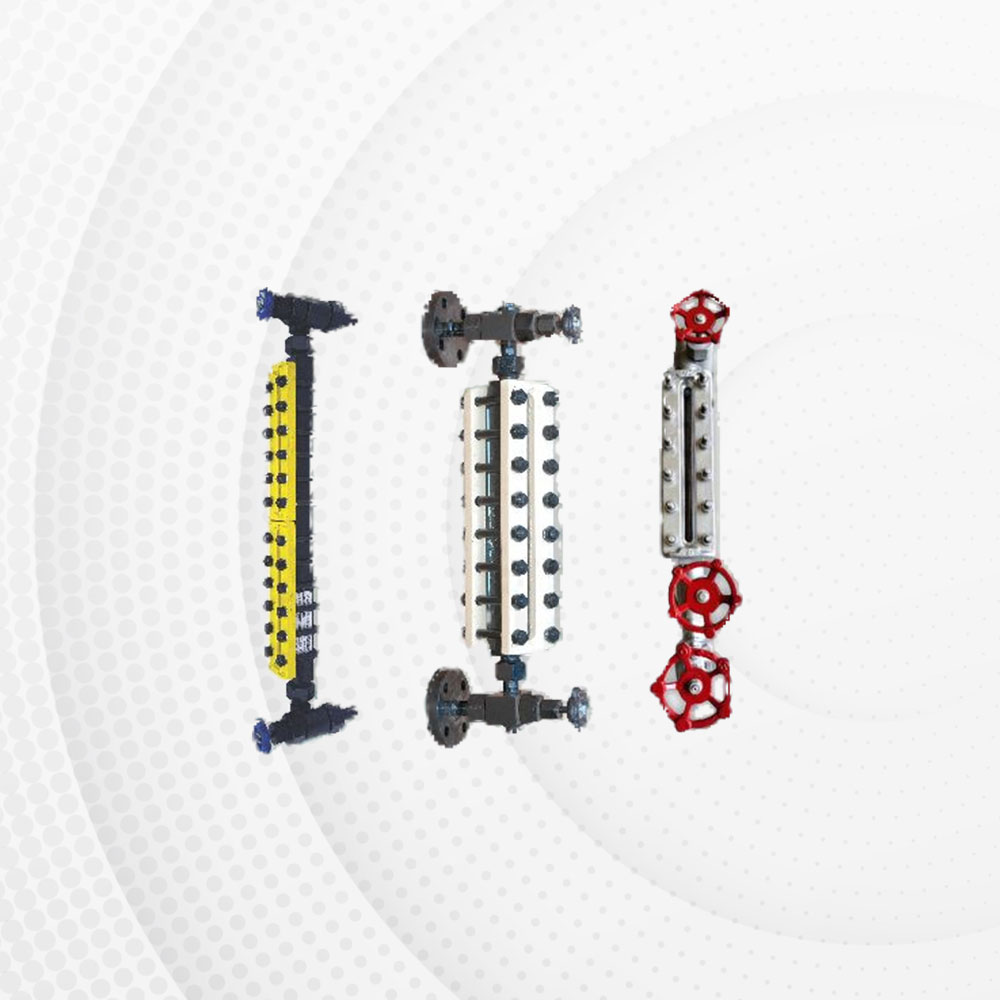

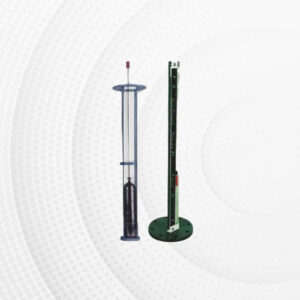

Reflex / Transparent Level Gauge Manufacturer

Reflex / Transparent Level Gauge (IBR Gauges)

Reflex level gauges are top-quality instruments used to determine the level of a liquid inside a container or vessel. They are widely employed in various industrial applications where accurate and secure fluid level monitoring is essential. These gauges are designed to help maintain the desired liquid level and facilitate industrial processes. They have minimal moving parts and can be utilized with a wide range of liquids, including those at high temperatures and with corrosive properties.

Reflex Level Gauge Features:

- Sturdy construction that can resist cracking and withstand challenging industrial conditions.

- Capability to operate safely in high-temperature and high-pressure environments.

- Clear and unobstructed windows that enable a distinct view of the liquid level.

Reflex Level Gauge Working Principle:

The working principle of reflex glass level gauges is based on the laws of light refraction and reflection. These gauges employ glasses that have one side facing the chamber, shaped with prismatic grooves having a section angle of 90 degrees. During operation, the chamber is filled with liquid in the lower zone and gases or vapors in the upper zone. The liquid level is distinguished by differences in the brightness of the glass in the liquid and gas/vapor zones. Reflex Level Gauges do not require specific illumination; natural daylight is usually sufficient. Artificial light is only needed for nighttime operation.

Reflex Level Gauge Applications:

Reflex glass level gauges are suitable for various applications and offer numerous advantages, including low initial and operating costs and easy level reading. However, there are cases where they are not recommended, such as when:

- Measuring the separation level between two liquids (interface) is necessary.

- Observing the color of the liquid is required in addition to level indication.

- The process fluid is high-pressure water steam, as mica shields must be used to protect the glass.

- The process fluid can corrode the glass, in which case mica or polytetrafluoroethylene (PTFE) shields should be used to safeguard the glass.

Frequently Asked Questions FAQs about Reflex Level Gauge

Yes, Reflex Level Gauges are engineered to withstand extreme pressures and temperatures.

Reflex Level Gauges can be adapted for use with corrosive liquids through the use of specific materials and coatings during their manufacturing.

Reflex Level Gauge Applications