IoT-Based Electromagnetic Flowmeter: Revolutionizing Data Analysis

In the realm of cutting-edge technology, Flowtech’s dedicated R&D team introduces an exceptional innovation – the IoT-based Electromagnetic Flowmeter, commonly known as Mag meters. These state-of-the-art devices harness the power of the Internet of Things (IoT) to provide real-time data-driven analysis, exemplifying Flowtech’s unwavering commitment to enhancing products and delivering top-notch quality assurance services to our esteemed clients.

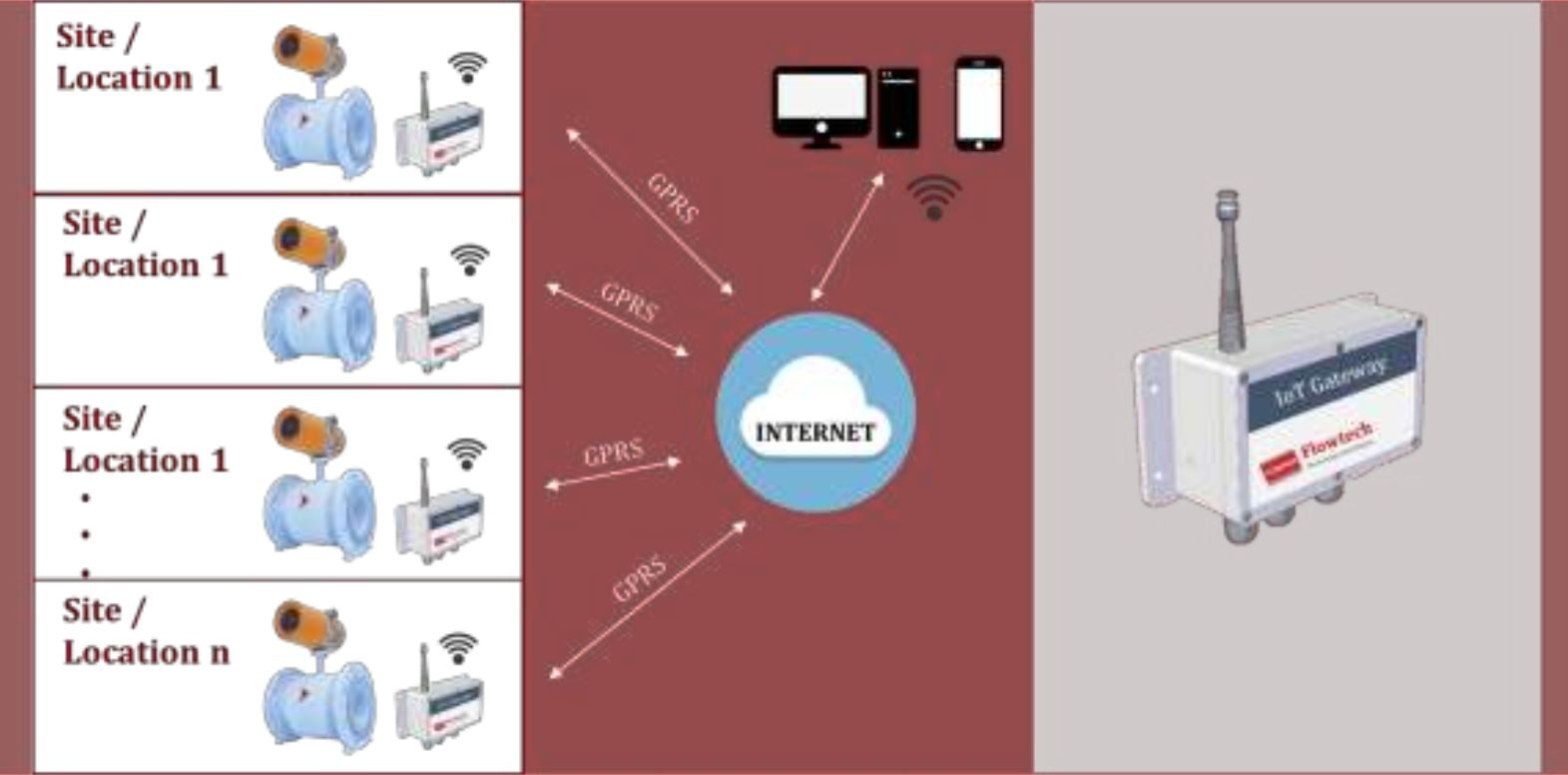

Unlocking the Potential of Flowtech IoT Gateway

The Flowtech IoT Gateway is purposefully engineered as a stand-alone IoT gateway, tailor-made for cloud-based applications, with a keen understanding of the diverse demands of modern industry. This cost-effective solution is highly customizable, catering to a wide array of Industry 4.0 applications. It harnesses the potential of Internet Connectivity through GPRS, 4G, Wi-Fi, or Ethernet.

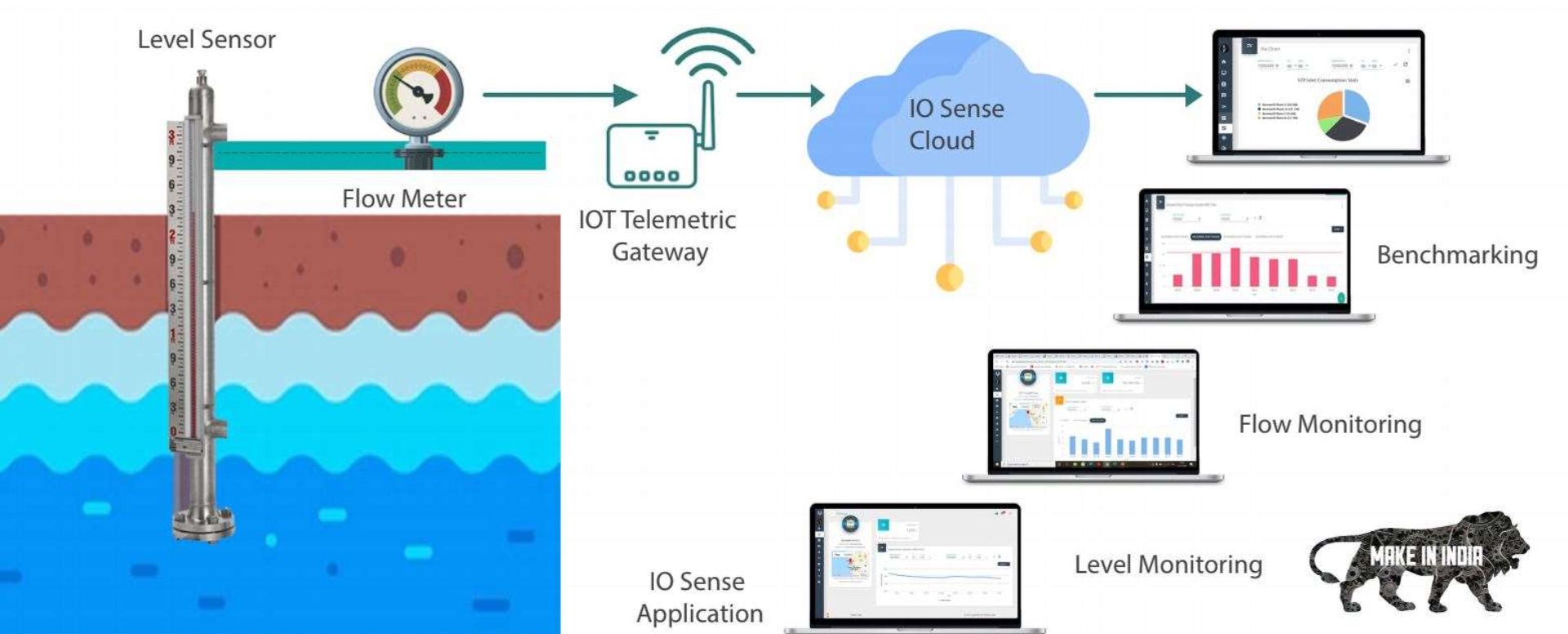

Adhering to CGWA Guidelines with IoT Flow Meters

In adherence to our latest technological strides, Flowtech’s IoT-based Flow Meters are meticulously crafted in compliance with the latest CGWA guidelines. A significant step forward is the mandate by the Gazette of India, dated 24 September 2020, requiring all industries to incorporate a telemetry system for groundwater monitoring. It is imperative to align with these new regulations, and Flowtech has consistently upheld its mission to deliver the finest quality in flow meters, underlining our dedication to engineering for reliability.

Key Features of Flowtech’s IoT Flowmeters:

- 360-Degree Monitoring: Enjoy 24/7 near real-time monitoring of Flow and Level data.

- Trend Monitoring: Analyze and compare water consumption and level trends across multiple borewells.

- MIS Reports: Automatically generate daily and monthly reports for internal use and sharing purposes.

- Alerts and Notifications: Set up alert levels to flag deviations when water consumption or level trends exceed permissible limits.

- Centralized Monitoring: Monitor all your borewells from different plants conveniently via a single platform.

- Multi-Hierarchy System: Access curated user accounts, facilitating data sharing for central teams, plant teams, and more.

With IoT-based Electromagnetic Flowmeters by Flowtech, harness the power of data analysis and real-time monitoring to usher your operations into the future. Embrace the digital transformation and ensure compliance with the latest industry regulations while reaping the benefits of advanced technology.