Table of Contents

Introduction: Are Smart Flow Meters Really Better?

Flow measurement technology has evolved dramatically, with smart flow meters offering real-time data, remote monitoring, and predictive diagnostics. But when comparing smart flow meters vs. traditional options like turbine, mechanical, or differential pressure models, is upgrading always the right choice?

The answer depends on your industry, budget, and operational needs. In this guide, we break down:

✔ Key differences between smart and traditional meters

✔ Cost comparison (upfront vs. long-term savings)

✔ Industries that benefit most from upgrading

✔ When sticking with traditional meters makes sense

Let’s dive in.

Smart Flow Meters vs. Traditional: Key Differences

1. How They Work

- Traditional Flow Meters

- Mechanical (turbine, positive displacement)

- Measure flow via moving parts (e.g., rotors, pistons)

- Require manual calibration & maintenance

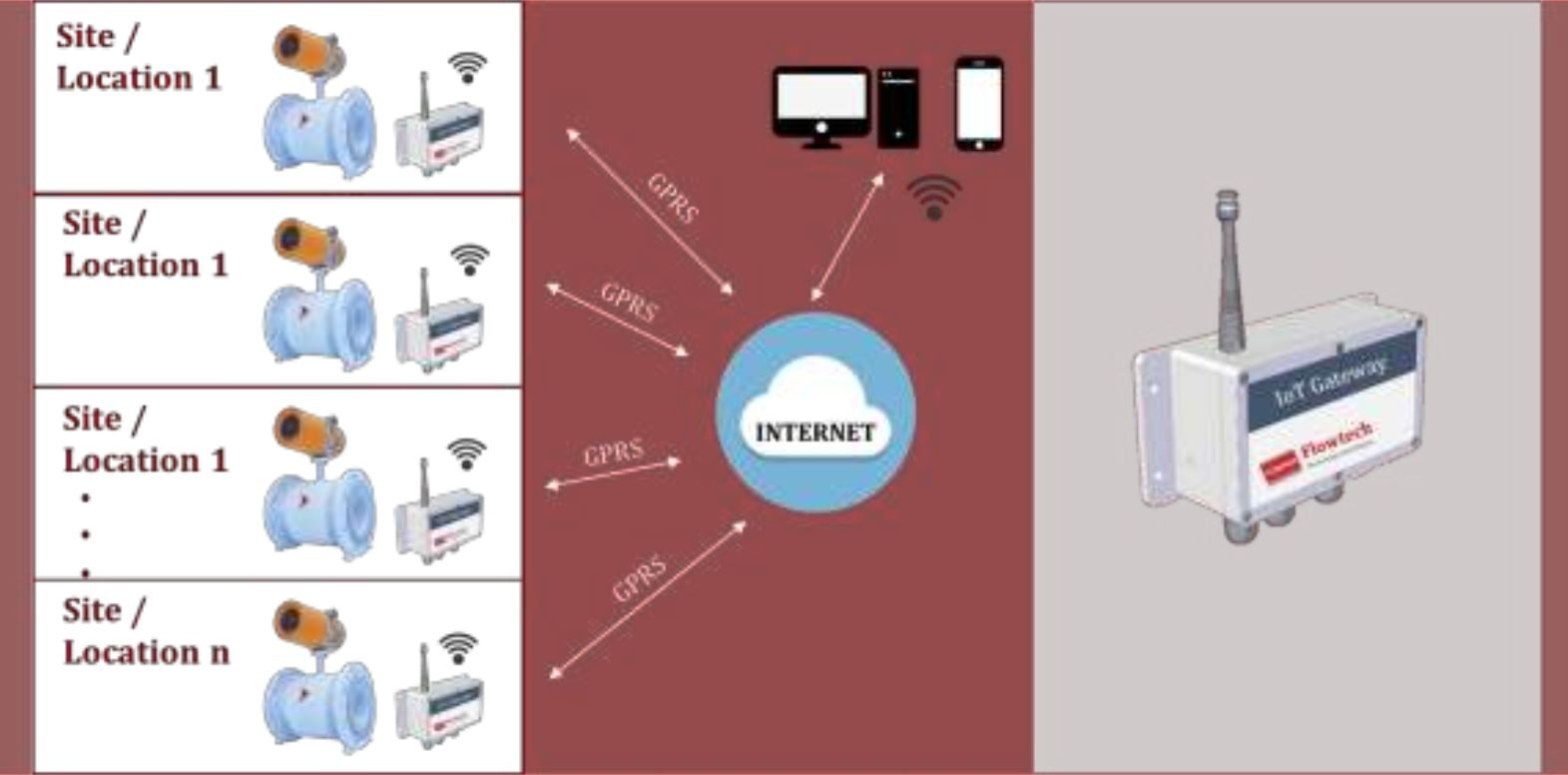

- Smart Flow Meters

- Digital (ultrasonic, Coriolis, electromagnetic with IoT)

- Use sensors & AI for real-time analytics

- Self-diagnose issues & send alerts

2. Accuracy & Performance

| Feature | Traditional Meters | Smart Meters |

|---|---|---|

| Accuracy | ±1-2% | ±0.1-0.5% |

| Turndown Ratio | 10:1 | 100:1+ |

| Maintenance | High (wear & tear) | Low (no moving parts) |

Example: A brewery using smart ultrasonic meters reduced measurement errors by 18%, saving $12,000/year in product waste.

3. Cost Comparison

| Cost Factor | Traditional Meters | Smart Meters |

|---|---|---|

| Upfront Cost | 1,000–5,000 | 3,000–15,000 |

| Installation | Simple | May require IT setup |

| Lifespan | 5–10 years | 10–15+ years |

| Long-Term ROI | Moderate | High (saves labor, reduces downtime) |

When Smart Meters Pay Off:

✔ High-value fluids (pharma, chemicals)

✔ Strict compliance needs (EPA, FDA)

✔ Remote or hard-to-access locations

When Traditional Meters Suffice:

✔ Low-budget operations

✔ Non-critical measurements

✔ Stable, predictable flow conditions

Industries That Benefit Most from Smart Flow Meters

1. Water & Wastewater

- Why Smart? Detects leaks early, reduces non-revenue water loss

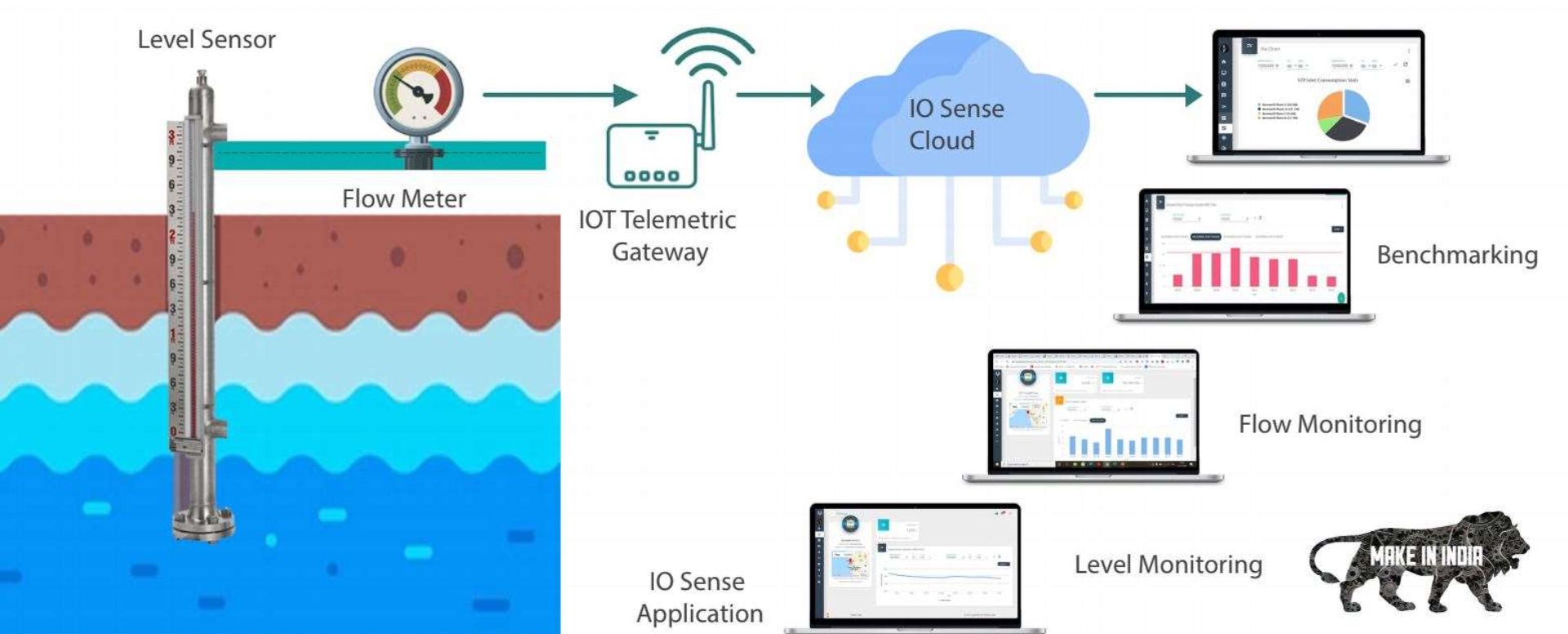

- Best Pick: Electromagnetic smart meters with cloud monitoring

2. Oil & Gas

- Why Smart? Handles multiphase flow, predicts equipment failures

- Best Pick: Coriolis meters with predictive analytics

3. Food & Beverage

- Why Smart? Sanitary design, reduces contamination risk

- Best Pick: Ultrasonic meters with CIP (clean-in-place) compatibility

4. Chemical Processing

- Why Smart? Tracks exact dosing, prevents costly errors

- Best Pick: IoT-enabled mass flow meters

5 Signs It’s Time to Upgrade

- Frequent calibration needs (smart meters self-calibrate)

- Unexplained measurement drift

- High maintenance costs

- Need for remote monitoring

- Regulatory compliance updates

The Verdict: Smart flow meters vs Traditional Is Upgrading Worth It?

✅ Yes, if:

- You need higher accuracy

- Downtime costs are high

- Remote access would improve efficiency

❌ No, if:

- Your current system works fine

- Budget constraints are tight

- Measurements aren’t mission-critical

Pro Tip: Start with a pilot program—install one smart meter in a critical area before full-scale adoption.

Need Help Deciding?

Still unsure whether smart flow meters are right for you? Our experts can analyze your setup and recommend the best solution. Contact us today for a free consultation!